Fabric inspection - 4-point system

source:KF Quality author:KFQ 2021-01-01 17:17:52

The examination of fabrics refers to ASTM D5430 “Standard test methods for visually inspecting and grading fabrics”.

Inspection condition:

- The overhead direct lighting source shall be mounted parallel to the viewing surface so as to illuminate with direct perpendicular impinging light rays. The surface illumination level shall be a minimum of 1075 lux.

- The light source shall be cool white preheat rapid start fluorescent lamps with white reflectors and without baffles or glues.

- The fabrics are to be inspected on an inspection machine at a speed is compatible with the fabric quality, but should never exceed 25 yards per minute for solid colors, and 15 yards per minute for printed/pattern fabrics.

- The fabric inspection quantity depends on the fabric types, about 1000 to 1500 yards per day.

Sampling:

- With shipments which total 1000m or yd or less, inspect and grade the total number of rolls or bolts.

- For shipments exceeding 1000m or yd, select samples per ISO 2859-1 or ANSI/ASQ Z1.4

Points assignment Option A (normally used):

- 0< Defect length ≤3 in. (75mm), assigned penalty points =1

- 3 in. (75mm) < Defect length ≤6 in. (150mm), assigned penalty points =2

- 6 in. (150mm) < Defect length ≤9 in. (230mm), assigned penalty points =3

- Defect length >9 in. (230mm), assigned penalty points =4

Notes:

a) Assig no more than a total of 4 points to any one yard of fabric, regardless of the number or size of the detected individual defects.

b) Assign 4 points to each consecutive yard in which a continuous running defect exceeds 230mm or 9 inches.

c) Assign 4 points to each yard of fabric where the usable width is less than the minimum specified.

d) Assign 4 points to each seam or other full width defect or seam if applicable.

e) Unless otherwise instructed, defects not visible on the face of the fabric shall not be counted.

Calculation:

Calculate the points per 100 sq. yd or sq. m.

Points / 100 yd2 = 3600 P/WL

Points / 100 m2 = 100000 P/WL

Where

P = Total points assigned,

W = Cuttable fabric width in. or mm,

L = Fabric length examined, yd or m.

Explanation on how coefficient 3600 or 100000 comes:

- 1 yd = 36 in.

- 1 m = 1000 mm

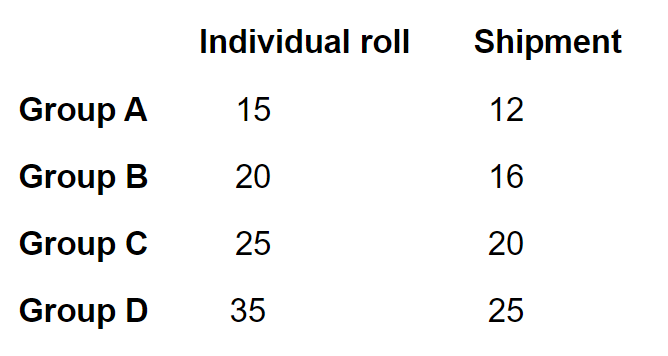

Advised acceptable “Penalty points per 100 sq. yd” – Group of fabrics

Note:

a) Group A: basic denim (open end spun /12-16 oz), dress shirting, worsted woolens, synthetics, polyester, nylon, acetate, filament

b) Group B: basic denim (ring spun /12-16 oz), light weight denim (4-8 oz), medium weight denim (9-12 oz), twill, canvas, poplin, oxford shirting, woolen spun, spun rayon, basic knitted fabric

c) Group C: plain weave fabric, stretch denim / stretch fabric, corduroy, velvet, chambray, silk fabrics, jacquard, seersucker

d) Group D: linen, linen/cotton, rayon blends

e) 1 point per 100 sq. m = 1.2 * (1 point per 100 sq. yd)

Other checkpoints during inspection of fabric:

- Weight tolerance: +/- 5% if < 10 oz / sq. yd; +/-3% if ≥10 oz / sq. yd

- Grey scale: 4-5.

- Bow / skew tolerance: 3% of overall width for solid color; 2% for yarn dye / printing

- Fabric length: 2% short from the ordered ticket

- Fabric width: must be more than claimed.

- Paper roll diameter: 1.5 in. -2.0 in.

- Hand feel, smell checks, color fastness test, tearing resistance and seam slippage test, stretching test, color bleeding test, etc.